- Our DNA

- Innovation Lab

- Publications

- Energy Transparency

- Press Corner

- Events

- Contact

- Subscribe

- Membernet

- My account

- Search

- Follow us at LinkedIn

- Follow us on Twitter

- Follow us on Instagram

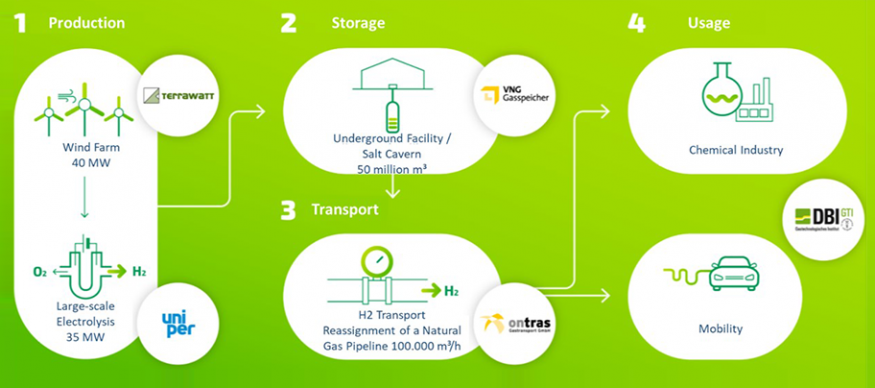

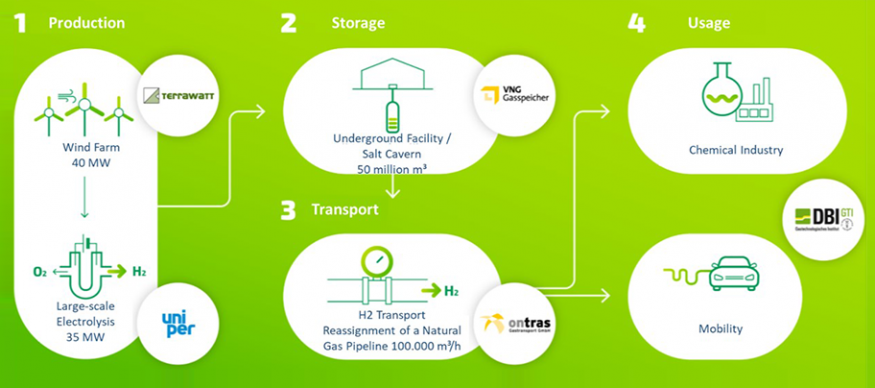

Bad Lauchstädt Energy Park is a large-scale power-to- gas project. Using a large-scale electrolysis plant of up to 35 MW, green hydrogen will be converted from a nearby wind farm using renewable electricity produced. Stored temporarily in a salt cavern specially equipped for this purpose, the green

hydrogen can be fed into the hydrogen network of the chemical industry based in central Germany via a dedicated gas pipeline and used in the future for urban mobility solutions It would be the first H2 cavern in continental Europe and the first such facility in the world for storing green H2.

Green H2 produced from renewable electricity using electrolysis is non-polluting and easy to store. It enables to compensate for weather-related fluctuations in solar/wind power generation and provides for efficient sector coupling. It will contribute to decarbonise mobility and industry sectors and will help promote large scale hydrogen projects. The project will boost research and accelerate market maturity of innovative H2 technologies: it will serve to test under real-world conditions and at an industrial scale. On the long-term, it will contribute to expend at large-scale the integration of green H2 in central Germany, and sector coupling technologies throughout the country and via EU.